Three dimensional printing in robotics

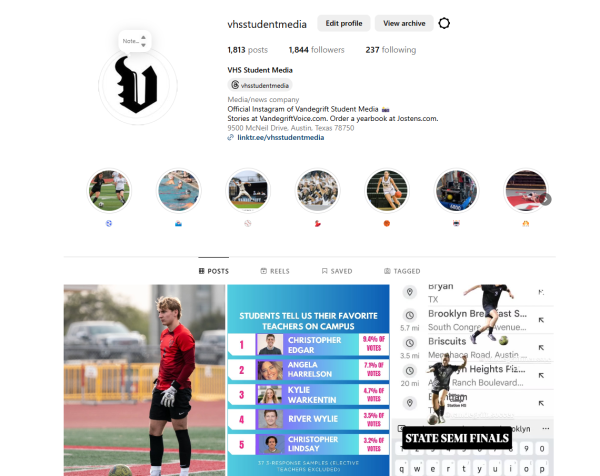

Andrew Cloran[left], Shaunak Pandey[middle], and Andrew Escott[right] pose next to their robot

September 27, 2021

A design is developed, original parts are turned to physical creation, and the three dimensional components of a robot are being fused together. The whirring of printers can be heard throughout the space, multiple machines running at once, and overseeing it all are the members of the robotics team.

Robotics has heavily used three dimensional printing in the design, creation and development of their robots for years. Printers allow them to efficiently create original parts for the construction of robots, contributing to their success in VHS’s achievements in competition.

“It’s an additive manufacturing technique,” senior Andrew Cloran said. “It works by depositing layers of plastic on other layers of plastic in a specific pattern to create three dimensional parts.”

On a computer, the entire robot is modeled out. Each piece is custom made.

“In addition to making pieces, having 3D printing also allows you to create a lot of backups,” junior Andrew Escott said. “Once we go into competition or something really important, [because] you want to have extras of these joints [that] break relatively easily, you can just go on the printer and print five more and then you’re good to go.”

With plastic being the only material that can be used with commercial printers, problems can arise surrounding the necessary durability needed of a part.

“They’re [3D printed parts] not always the strongest,” Cloran said. “Due to the way the layers add up, it can fracture in the right direction with ease.”

A solution to these breakage problems lies in the utilization of alternate types of plastics and Markforged printers.

“We have the Markforged printers over there, which are unlike most printers,” Cloran said. “They actually have the ability to add a continuous fiberglass strand through the parts, which is extremely strong.”

In their latest robot, bearing blocks were printed to hold the linear telescoping tubes of the structure in place.

“They’re super custom and extremely hard to manufacture in any other traditional machines so 3D printing lets us make that and hold all the bearings in the right spots,” Cloran said.

Finding the right spot for each part is essential to the construction of a robot.

“In robots, 18 by 18 space constraint, having the ability to construct 3D parts enables your robot to be much more elegant and efficient and it all fits together, completes its function,” sophomore Shaunak Pandey said.

While the printing process “sounds difficult,” it’s “really kind of straightforward” (Pandey).

“Obviously once you get into designing complex pieces like this it’s difficult but the overall CAD (computer aided design) of printing is really simple and I think that’s why a lot of people are using 3D printers these days,” Pandey said.

Outside robotics, other students can benefit from using three dimensional printers.

“I really think aerospace could benefit from this because I know there’s new technologies of 3D printed drones and planes and stuff because they’re disposable, you can easily reprint it,” Pandey said.

Printing introduces a unique method of design and construction that sparks ample opportunities for students to immerse themselves in a new outlet they didn’t know they were missing.

“I remember when I was younger and they[3D printers] would be expensive,” Pandey said. “It would be hard to get your hands on one and I never got my hands on one but in robotics, with so many 3D printers, it gave me the opportunity to use them. It’s super cool.”

![Andrew Cloran[left], Shaunak Pandey[middle], and Andrew Escott[right] pose next to their robot](https://www.vandegriftvoice.com/wp-content/uploads/2021/09/Screen-Shot-2021-09-27-at-11.14.49-AM-702x900.png)